Dr. Samuel Lee, Thomas Sangwook Lee, and Michelle Kim describe their research with a dental implant osteotomy without water coolant.

Dr. Samuel Lee, Thomas Sangwook Lee, and Michelle Kim study a way to collect autogenous bone from the osteotomy

Abstract

This study investigates a novel approach to dental implant osteotomy, aiming to simplify the procedure by employing a single drill without the use of water coolant. Traditional methods involve multi-step drilling with saline irrigation to manage heat generation and preserve tissue integrity. However, these approaches can introduce complications and inconvenience. In contrast, the proposed single-drill protocol eliminates the need for multiple steps and irrigation. This new approach allows surgeons to collect autogenous bone from the osteotomy. Using thermal cameras, the study assesses the temperature changes during osteotomy and evaluates the safety and efficacy of this innovative approach. The study encompasses three key aspects:

- An examination of the effects of various drilling techniques on bone temperature,

- An exploration of the relationship between drill dimensions and thermal conductivity

- A retrospective analysis of the success rate of the single-step osteotomy without coolant in a clinical setting.

Findings indicate that the single-step osteotomy protocol, when executed with precision, can maintain bone temperatures below critical levels without the need for water coolants. This innovative approach offers potential benefits in terms of surgery simplification and reduced patient and operator stress, particularly in complex dental procedures. The study underscores the importance of new drill technologies that collect bone while simplifying surgery and improving the efficiency and safety of dental implantation.

Introduction

Eriksson, et al., established 47 degrees Celsius as the critical temperature at which bone cells necrose in a rabbit model when drilled for more than one minute.1 Furthermore, 44 degrees Celsius (111.2 Fahrenheit) is recognized to be the threshold at which necrosis does not seem to occur. To maintain cell viability during oral implantation, many clinicians advocate for multi-step drilling combined with saline coolant. In this article, we aim to explore the use of a single-drill protocol as an alternative technique for oral implantation that eliminates the need for multi-drilling protocols and saline irrigation. This is because the conventional multi-step drilling protocol can lead to increased complications such as contamination and inconvenience by showing it does not result in necrosis in the cell and does not generate heat when kept below 44 degrees Celsius (111.2 Fahrenheit), which is where necrosis seems to occur. This is because while water coolants like saline irrigation assist in reducing temperatures, they can also introduce complications such as choking, laryngospasm,9 saliva contamination, and loss of bone from the drill.

In this study, a hollow drill without irrigation is used to preserve the bone collected from the osteotomy and reduce frictional heat from bone debris. Our study aims to assess the effectiveness of thermal cameras in monitoring temperature elevation during osteotomy and to evaluate the safety of a single-step osteotomy utilizing a hollow drill without the use of water coolants.

Methods

Our methodology consists of three distinct parts.

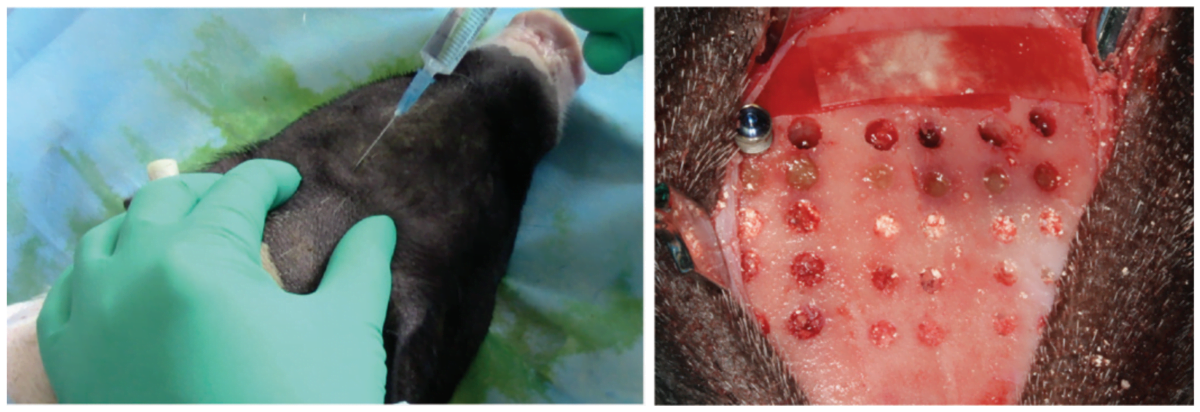

First, 156 osteotomies were performed on a pig ciborium under conscious sedation with pentobarbital administered intramuscularly to the left buttock, and local anesthesia was injected into the scalp with lidocaine with 1:100k epi as approved by the e5ic committee of University of Guanxzi in Nanning, China (Figure 1). An incision was made on the scalp using a No. 15 scalpel blade, followed by the use of a periosteal elevator to expose the calvarium bone. Calvarium bone was chosen for easier access, offering 6 mm to 7 mm of cortical bone, and since it also ossifies via intramembranous ossification similar to mandibular jaw bone. A 3.8 mm diameter implant was drilled to a depth of 7 mm to install a 4.5 mm x 7 mm titanium implant fixture. Throughout the osteotomy, a thermal camera (specs: 206 x 156 thermal sensor; Leaton, California) was employed to monitor the heat generated on the bone of different drill techniques to assess their effects on the pigs’ bones. We compared multi-step osteotomy with and without irrigation, single-step drilling using new hollow drills at various speeds and contact times, and piezo with and without water coolant.

For part two of the study, we compared the thermal difference between the tip of the drill and the shank of the drill in various diameters and lengths to evaluate if the measurement of the shank’s temperature can be used to detect thermal damage at the tip of the osteotomy.

For the third part, we conducted a retrospective study of the success rate of the using one-step osteotomy without irrigation on 979 dental implants (585 in the maxilla and 394 in the mandible) on 267 patients in San Diego, California.

Results

-

Part 1: Temperatures in pig models and drilling techniques

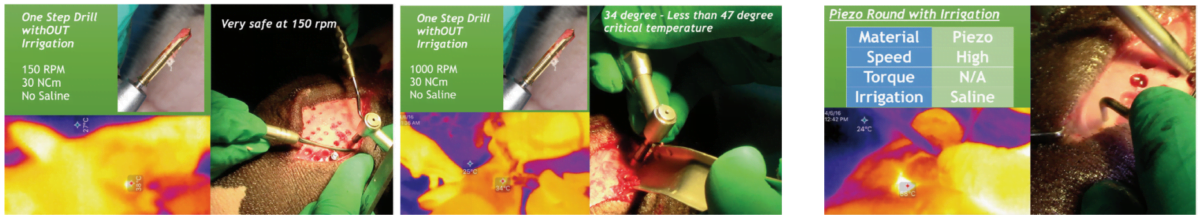

Seven different drilling techniques were tested to assess their effects on the bone. Additionally, multi-step osteotomy without irrigation was tested that included:

- single-step osteotomy with irrigation (1000 rpm)

- single-step osteotomy without irrigation (150 rpm)

- single-step osteotomy without irrigation (1000 rpm)

- piezo with irrigation

- piezo without irrigation

The authors drilled 30 osteotomies of each drilling technique into four of the pigs and collected data on the heat generated. The study found that only the piezo with irrigation and the piezo without irrigation techniques failed to stay under the critical temperature (44° C/111.2° F) that can cause damage to most human tissues.1 Figure 2 shows the average temperatures of all the bones of the pigs through the seven drilling techniques.

-

Part 2: Temperature ratios in the tip of drills versus shank

One of the main difficulties in many studies regarding drill friction temperatures is the methodology used to measure at the tip of the drill. Because these drills are typically deep into bone or tissue, it is physically challenging to assess the temperature of the tip of a drill when it is being used. As a result, we decided to create a statistical model to help predict the temperature of the tip of the drill through the temperature of the shank. This was performed by measuring two different variables. The authors tested the drills of different widths (Figure 4) and tested them at different times (1 second, 3 seconds, and 5 seconds of heating during usage). For each sample, the tip of the drill was heated to 44 degrees Celsius (111.2 Fahrenheit) and then collected the temperature of the shank. This was then divided the temperature by the shank by 44 degrees Celsius (111.2 Fahrenheit) to find the ratio between the temperature of the tip and the shank. One-hundred samples were collected for each drill each time, and a general trend was found within 5 and 3 seconds of heating (Figures 10 and 11). In Figures 10 and 11, there was a general downward trend and then an upward trend afterward. Thus, it was hypothesized that this is due to the surface area and volume ratio, as objects with greater surface-area-to-volume ratios generally conduct heat faster.

Figure 11 is more volatile and does not follow the trends Figures 5 and 6 follow. However, this is likely because heating for 1 second is so short that it did not have much of an effect on the temperature of the shank. The differences between the different widths of drills in Figure 11 are not statistically significant, so a trend cannot be established.

The findings within part 2 help establish the general trends between the thermal conductivity of drills and the temperatures of the shank of drills in relation to their tips. These findings can help estimate the heat of the tip of drills in 10.0 mm length in different time intervals. However, more analysis and additional models are recommended for data on different types of drills.

-

Part 3: Patient data on one-step osteotomy

A retrospective study of 267 patients from September 1, 2020 to October 10, 2023, in a dental implant institute in San Diego received 979 dental implants (585 in the maxilla, Figure 8) and 394 in the mandible (Figure 9) using a one-step (single) osteotomy technique without water coolant. As seen in Figure 10, the success rate of these implants outperforms compared to the traditional dental implant success rates reported by Papaspyridakos et al., (2012).8

Discussion

Part one of the study presents a comprehensive comparison of various drilling techniques against a critical temperature threshold of 44 ° C/ 111.2° F. All other methods, except for the piezo technique, both with and without irrigation, remained below this critical temperature. Consequently, the study indicates that conducting a single-step osteotomy without irrigation at speeds below 1000 rpm for short durations not exceeding three seconds effectively maintains bone temperatures below potentially hazardous levels within the pig model. In order to further ensure low thermal damage, lower speed can be employed, suction placed near the osteotomy (Figure 6A), and use of a new sharp instrument (drill). Figures 4A, 4B, and 8 show both multi-step and one-step osteotomy without water coolant. These groups all showed lower temperatures than thermal damage temperature (44 ° C/ 111.2° F). Therefore, water coolants are not necessary if the surgeon employs the precautions mentioned above.

Hollow drills offer implant surgeons the following advantages:

- They reduce frictional heat by removing bone particles away from the osteotomy into the center of the drill.

- They collect autogenous bones to be used for grafting. The best use of a step hollow drill is without coolant, as the irrigant can wash away the bone particles.

Interestingly, the hollow drills offered lower temperatures when used at higher speeds at 1000 rpm versus 150 rpm, as seen in Figure 8. This is true when pumping the drill up and down as it cools down from rotating air. The bone collected from this hollow drill is used to augment the dental implant, as seen in Figures 15 to Figure 18.

more complex procedures such as sinus bone grafting. Autogenous bone collected from the hollow

drill makes the bone heal faster

In the study, an up-and-down motion was used to decrease contact time between the drill tip and the bone and to measure the temperature of the tip. This technique is recommended especially when not using saline irrigation to cool down the drill to prevent reaching the critical thermal damage temperature.

If a surgeon does not employ up-and-down motion without irrigation, the tip of the drill might exceed the critical temperature since the thermal camera can only detect the surface temperature (shank or bone surface). In Part 2 of our study, we aimed to find the ratio between the tip and the shank of the drill. Our result suggests that there is a statistical trend between the diameter of the drill (Figures 10-12) of 10.0 mm length drills and their thermal conductivity when heated for 3 seconds or 5 seconds. The authors hypothesized these trends to be a result of the ratio between the surface area of a drill and the volume of the drill. However, further research is suggested to find statistical validity for that hypothesis. In this study, there was no notable trend when heated for 1 second. The authors believe this to be the case because 1 second is likely not enough time for heat to travel to the drill’s shank. As a result, the trends found within our study cannot be applied to cases in which the drill is heated for less than 3 seconds.

One-step osteotomy without irrigation simplifies the surgery and reduces surgical time. It reduces stress for the operator and the patient. In addition, it allows the surgeons to collect autogenous bone from the osteotomy, which in turn, can be used in complex cases involving sinus lift or vertical ridge augmentation. Most osteotomies ended in 5 seconds due to a simplified approach to dental implantation. There are three very important requirements to achieve a successful “one” drilling protocol.

- In order to ensure sharpness of the drill, our group recommends a new drill for each surgery. Repeated use of drill and autoclave processes have been known to dull the drills.

- Fully guided surgery is highly recommended. When using a step protocol, there is no guiding pin involved, nor is there any subsequent drilling to rescue malangulation of the osteotomy.

- Implant morphology should accommodate bone den For maxillary bone, a smaller pitch and wider crystal body is recommended. For mandibular bone, a higher pitch and narrower crystal body is indicated. The pointed apex allows self-tapping of the implant without bottoming out in case the surgeon wishes to place the fixture deeper. This study shows that the success rate is over 97% on both maxilla and mandible. Long-term follow-up (> 5 years) is not available, but should thermal necrosis happen, it is within weeks after implantation. Therefore, if the failure resulted from thermal damage during osteotomy, we can observe it within 6 months of follow-up. The authors believe that a single drill without coolant results in faster surgery and less stress for the patient and the operator. This can be attributed to a higher success rate, especially if the procedure involves more complicated bone morphology needing sinus lift or ridge augmentation, the use of autogenous bone collected from the hollow drill gives an unparalleled advantage to surgical healing as autogenous bone is the gold standard. For example, the case in Figure 10 involves a sinus lift. Since the osteotomy was simple, the surgeon was able to concentrate more on sinus grafting. Furthermore, the autogenous bone collected from the hollow drill mixed with FDBA resulted in faster healing. As discussed earlier, in a maxilla with minimal bone height, it is critical to use an implant with a higher pitch and a larger crystal body to achieve good initial stability. Figure 11 shows 3-year follow-up showing bone preservation without any bone loss.

Another challenge in implant dentistry is vertical ridge augmentation. By utilizing the “one-drill” protocol, the surgeon simplifies the installation of the dental implant, thereby giving more time to the bone augmentation procedure. Again, the autogenous bone collected from the drill is reused with FDBA in these challenging cases. Autogenous bone gives osteogenic and osteoinductive properties. However, it is not very osteoconductive as bone particles are very small. Therefore, mixing with FDBA supplements this mixture very well since FDBA is good osteoconduction. Figure 17 shows vertical bone loss due to periodontal abscess. Upper centrals are extracted, and a “one-drill” protocol with guided surgery has been performed. Autogenous bone mixed with FDBA bone is used to augment before the insertion of a dental implant. Newton Implant (San Diego, California) 4 mm x 13 mm fixtures are placed with excellent torque due to their sharp apical shape and aggressive thread design. 3 year follow-up shows excellent bone maintenance and healthy peri-implant tissues, as seen in Figure 18.

Conclusion

A traditional multi-step drilling protocol with saline coolant has been used for decades as proposed by the original Brånemark Protocol. However, using the new one-drill protocol with a new hollow drill, computer-planned and guided, and innovative dental implant design helps oral implantologists to minimize surgical time and reduce stress to our patients. In addition, the hollow drill allows autogenous bone collection, which can be used in complex procedures such as vertical and horizontal ridge augmentations as illustrated in this article.

- Eriksson RA, Albrektsson T. The effect of heat on bone regeneration: an experimental study in the rabbit using the bone growth chamber. J Oral Maxillofac Surg. 1984 Nov;42(11):705-711.

- Moritz AR, Henriques FC. Studies of Thermal Injury: II. The Relative Importance of Time and Surface Temperature in the Causation of Cutaneous Burns. Am J Pathol. 1947 Sep;23(5):695-720.

- Lundskog J. Heat and bone tissue. An experimental investigation of the thermal properties of bone and threshold levels for thermal injury. Scand J Plast Reconstr Surg. 1972;9:1-80.

- Eriksson RA, Albrektsson T, Magnusson B. Assessment of bone viability after heat trauma. A histological, histochemical and vital microscopic study in the rabbit. Scand J Plast Reconstr Surg. 1984;18(3):261-268.

- Eriksson AR, Albrektsson T. Temperature threshold levels for heat-induced bone tissue injury: a vital-microscopic study in the rabbit. J Prosthet Dent. 1983 Jul;50(1):101-107.

- Eriksson AR, Albrektsson T, Albrektsson B. Heat caused by drilling cortical bone. Temperature measured in vivo in patients and animals. Acta Orthop Scand. 1984 Dec;55(6):629-631.

- Bonfield W, Li CH. The temperature dependence of the deformation of bone. J Biomech. 1968 Dec;1(4):323-329.

- Papaspyridakos P, Chen CJ, Singh M, Weber HP, Gallucci GO. Success criteria in implant dentistry: a systematic review. J Dent Res. 2012 Mar;91(3):242-248.

- Kim JY, Chae M, Lee J. Operative hysteroscopy intravascular absorption syndrome caused by massive absorption of 0.9% saline as the distention/irrigation medium. Korean J Anesthesiol. 2013 Dec;65(6 Suppl):S44-46.

Stay Relevant With Implant Practice US

Join our email list for CE courses and webinars, articles and mores

Samuel Lee, DDS, DMSc, is an innovator with a passion for teaching and developing new technologies. Dr. Lee obtained two doctorate level degrees: Doctor of Medical Science and a specialty degree in Periodontology from Harvard University, as well as his Doctor of Dental Surgery from UCLA. He invented the “Crestal Window Sinus Grafting Technique,” and owns the patent on various sinus and surgical instruments. He also introduced a new method of dental radiography that uses ultra-low dosage radiation and allows for angulation correction, enhancing 3D imaging capabilities. As the Founder and Director of the International Academy of Dental Implantology, he focuses his career on teaching and doing research. Among many other distinguished achievements, he has trained over 10,000 dentists worldwide in implant dentistry, developed a new method of dental x-ray, and designed advancements to surgical tools. He travels internationally, lecturing on his sinus techniques and TADs to surgical specialists, general dentists, and dental schools.

Samuel Lee, DDS, DMSc, is an innovator with a passion for teaching and developing new technologies. Dr. Lee obtained two doctorate level degrees: Doctor of Medical Science and a specialty degree in Periodontology from Harvard University, as well as his Doctor of Dental Surgery from UCLA. He invented the “Crestal Window Sinus Grafting Technique,” and owns the patent on various sinus and surgical instruments. He also introduced a new method of dental radiography that uses ultra-low dosage radiation and allows for angulation correction, enhancing 3D imaging capabilities. As the Founder and Director of the International Academy of Dental Implantology, he focuses his career on teaching and doing research. Among many other distinguished achievements, he has trained over 10,000 dentists worldwide in implant dentistry, developed a new method of dental x-ray, and designed advancements to surgical tools. He travels internationally, lecturing on his sinus techniques and TADs to surgical specialists, general dentists, and dental schools. Thomas Sangwook Lee is a researcher at The International Academy of Dental Implants. He is a predental student at Santa Fe Christian School. His goal is to become a dental implant surgeon. He holds patents on a unique thermosensor for oral surgery.

Thomas Sangwook Lee is a researcher at The International Academy of Dental Implants. He is a predental student at Santa Fe Christian School. His goal is to become a dental implant surgeon. He holds patents on a unique thermosensor for oral surgery. Michelle Kim is a researcher at The International Academy of Dental Implants. She is a predental student at University of California, San Diego. Her goal is to become a dental implant surgeon.

Michelle Kim is a researcher at The International Academy of Dental Implants. She is a predental student at University of California, San Diego. Her goal is to become a dental implant surgeon.