Editor’s intro: 3-D printed dentures represent a new vision for dentistry. While still in its infancy, 3-D printing offers potential to raise the bar on accuracy and esthetics — read more about the learning curve and possibilities for this technology.

Joseph Lee, CTO at Friendship Dental Labs, shares his vision of 3D printing for the denture and implant practice

What are 3D-printed dentures?

3D-printed dentures are a paradigm shift away from a traditional perspective on what a denture is. While many labs offer dentures, few actually do a good job in the traditional sense. If a veneer has a defined parameter (margin, thickness, etc.) a denture is all about tolerances to achieve success. 3D-printed dentures offer the potential for a level of accuracy and esthetics that were truthfully only accessible by a few. To me, a 3D-printed denture is the future capstone for the removable space in dental.

What is the process? What are some benefits or potential challenges?

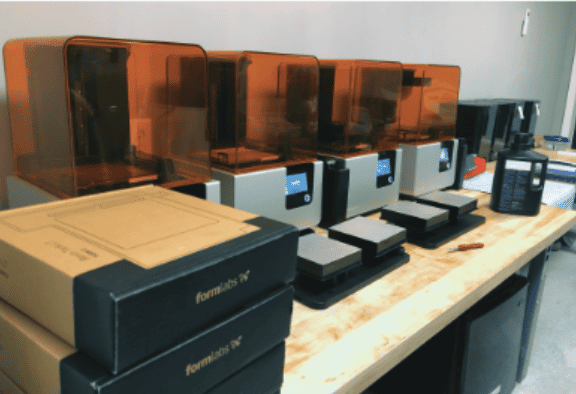

The immediate benefit of printing dentures is “footprint.” The 3D-printed space really requires only your CAD workstation, a Form 2 printer or their brand-new Form 3 printer, Form Wash + Form Cure with some Pyrex® and glycerin. Additionally, you would need a polishing station and an area to do composite staining if you wanted. All in all? A 60″ sturdy table would suffice.

The biggest hurdle is the lack of edentulous scanning solutions today. I’ve had ideas of shrinking NDT methods, but we are still far from that. Or even being able to digitally map a scaled-up form of DH-QPM? Right now our best solution is scanning the impression, but typically a removable impression requires quite a bit of work even after being poured up — so scanning the impression is also still a limiting solution. With that being said, one of the largest hurdles is proper records.

The second largest hurdle with 3D-printed dentures would be the stigma behind quality. Companies tout the simplicity — which, invariably, clinicians perceive as “cheap and affordable.” If a 3D-denture breaks today, there isn’t the notion that maybe our perceived requirements for design need to be shifted. Instead it’s an immediate crucifixion that this “technology” is cheap and broken.

The biggest benefit to printing over packing, injecting, or milling is the opportunity to create the best-fitting denture in the world. Hypothetically, you don’t need to post-dam the case, wax over undercuts, etc. If the scan is of good quality, and it’s accurate, what is designed off of that can achieve new levels of intimate fit.

The biggest challenge in the lab is deciding how far you want to go with your esthetics. Right now, we highly suggest composite veneering and characterization for final dentures, but none for immediate dentures.

Is there a big learning curve?

Yes, but it is related to how the dental space has fostered experience in removables. Usually the oldest, most experienced technicians are the ones who carry the torch in most removable departments. Unfortunately, that also usually means that the learning curve to design on a Wacom® Cintiq using a 3D space mouse is very difficult to adopt. In fact, we saw better adoption using virtual reality (VR) (HTC Vive Pro) than any other style of digital design. Additionally, production schedules drastically change because this process deviates so greatly from traditional denture fabrication.

Truthfully, the biggest learning curve is patience.

What type of other equipment do you need to go with it?

A good scanner and good CAD software.

I highly suggest designing on a Wacom Cintiq Pro and pairing it with nothing below an 7700K (9900K preferred) and a 1080Ti or even better a RTX2070 (or higher). The best space mouse to use is not the larger ones, but the wireless Bluetooth one from 3Dconnexion.

It’s VERY important to have a proper digital denture tooth library. Right now, the best one on the market is is the Ivoclar Vivadent tooth library: SR Vivodent® S DCL.

It’s very easy to scale with form. Start off with a Form 2 and the Form Cure.

The flowable composite by anaxdent North America is great, as is the Creation VC light curing composite system by Creation Willi Geller (which fluoresces, by the way).

Before jumping in and purchasing or even leasing a printer, a very strong reason to go with Formlabs will be what you need. Few printers are doing multi-head prints, so if you scale, you scale with the need for more printers as well. It’s easier to have two to four or even six Form 2’s than it is to spend $15,000 and then $45,000, just so you can simultaneously print different gum shades and tooth shades.

Very important question for our readers — how does this process help implant dentists serve their patients better, more efficiently, quicker (any other ways that it may help).

With regards to implant dentistry, we have barely scratched the surface. Right now, we are only looking at printing immediate dentures for faster turnaround time. It’s not just dentures; it’s the way cases are planned, staged, prepped, and the types of prosthesis we can make that haven’t even been thought of yet.

In terms of how this process helps implant dentists serve patients better, it’s the following:

- Being able to create densities and bone structure under other structures to perfectly plan out the surgery/practice.

- Being able to replicate the surgery with other technologies and provide a perfect implant denture with no conversion process.

- It’s not just the denture itself, but being able to use the denture tooth materials for other things, and also rapid printing in case something breaks.

- All files are digital, so we can always replicate what we’ve made.

For implant-focused dentists, does 3D printing entail making your own surgical guides for implant surgery? How does this create more accurate implant placement?

Yes, for implant-focused clinicians, 3D-printing enables them the option of printing their own guides. The guides, as long as they are designed right, provide the opportunity for better placement.

How quickly can these guides be made in office?

Printing the guides themselves takes only about 90-ish minutes. Between sterilization and post-processing, you could easily finish your own guide in a day.

Is it difficult to design and print 3D-surgical guides in the office?

It’s not difficult to print guides in the office. There are varying difficulties with regards to software — but the bigger question that needs to be asked is where is your time most valuable? In-house printing is a lovely notion, but it is still messy, and clean space or any sort of extra space in the office is a luxury. We’ve necessarily always there.

Seeing is believing! After reading about 3-D printed dentures, see the possibilities for 3-D printed surgical guides! Check out a webinar on the digital workflow for 3D printing.

Stay Relevant With Implant Practice US

Join our email list for CE courses and webinars, articles and mores